23/08/21

Ana Cross, AHU Product Manager at Elta Fans

As a business, Elta Fans is focused on delivering improvements to air quality within the built environment. We’ve now reinforced that commitment with the installation of a PREMA 540 ventilation system at our head offices in Kingswinford.

The project

The project started back in April 2020, when we decided to use the reduced occupancy in the building as an opportunity to make physical changes to the space, including altering the internal layout. As standard, this would require a re-assessment of ventilation strategy anyway, but we also wanted to take this chance to really improve the IAQ within our office.

The COVID-19 pandemic has changed perceptions of the air we breathe, and while at Elta Fans we have always been acutely aware of its importance, this seemed like the right time to invest in cutting-edge ventilation. We opted for the PREMA 540 air handling unit with an electric heater, to ensure that we could maintain ambient temperature for staff, all the while improving the internal air. As all of our PREMA products are fitted with fine filters (ePM1 55%) on supply, we could be confident that it would remove respirable particles from incoming air.

The results

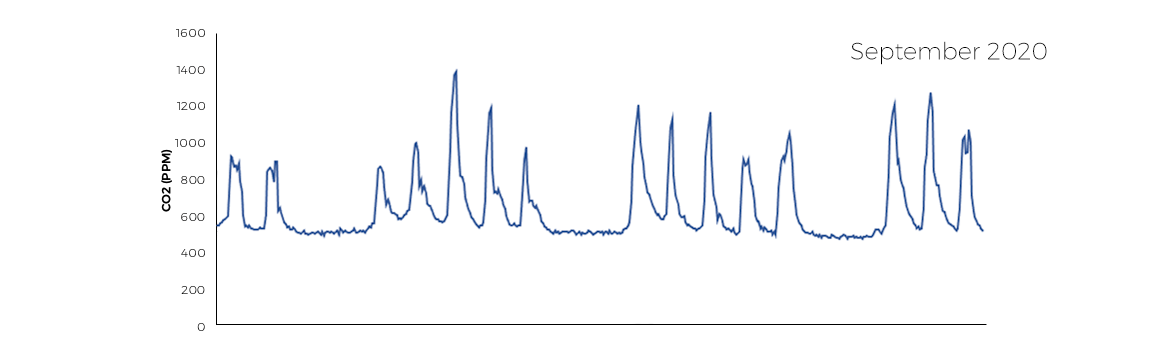

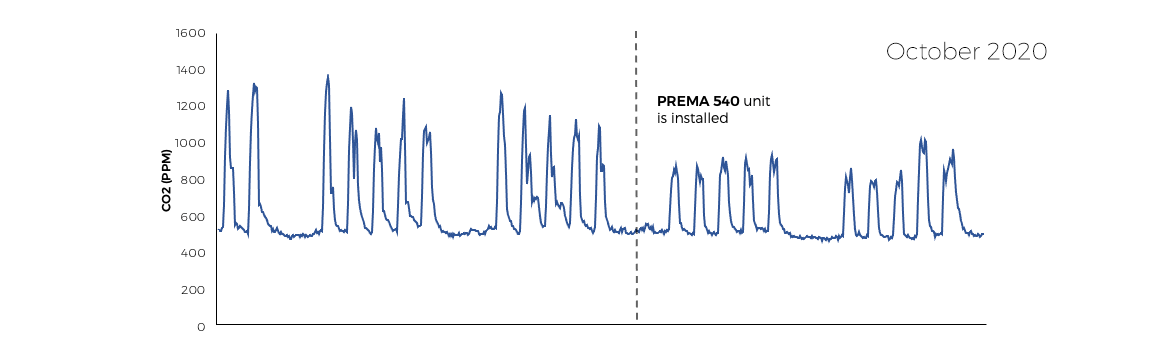

The data speaks for itself. Graph 1 highlights the month of September, indicating the CO2 (ppm), peaking at 1400ppm on a standard working day. This compares with Graph 2, October, which shows the point at which the AHU was installed (halfway through the month).

The results have been fantastic. Since getting the system fully up and running, we have seen a 33% decrease in peak CO2 levels throughout the working day, down to a peak of 1000ppm. The fact that the system is demand-controlled has also allowed us to adapt to the various lockdowns, meaning that it only works as hard as it needs to depending on occupancy levels.

The explanation

This is something that all systems should work towards. It’s not just good for adapting to extreme circumstance changes such as lockdowns, but also for altering flow rates according to day-to-day requirements. It may be that the office is less busy over a period of time (be that due to lockdown, working from home patterns, or staggered start times), or that there is a particularly high amount of outdoor pollution that week. Whatever the reason, demand-controlled ventilation such as this is great for ensuring IAQ is achieved, without incurring high running costs.

This is further improved thanks to a low-energy consumption EC motor on both supply and extract fans, as well as a high efficiency aluminium core counterflow air-to-air exchanger. Where natural ventilation, such as opening a window, causes heating and cooling systems to work harder in order to maintain ambient temperature, the PREMA 540 allows thermal energy recovery (heat or cool load) from the stale air into the incoming filtered air to reduce the building’s overall energy output.

The future

We’ll continue to monitor the data into the future, as this helps to ensure air quality remains at an optimum level. Sophisticated monitoring is something that all buildings and indoor spaces should work towards, especially as structures are becoming increasingly energy efficient and airtight, therefore presenting a danger that other types of outdoor air pollution will become trapped.

We’re proud to have an office that prioritises the health of its occupants, by continuously monitoring CO2 and other types of pollutants including PM2.5, TVOC’s, NO2, as well as relative humidity. It’s a core part of our ethos, and to demonstrate tangible improvements to our IAQ is an important step for the business.

Check out our range of AHUs here